Byproduct Recovery Circuit Being Tested at Key Lake Operation

January 2, 2014

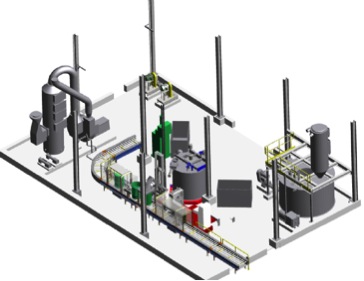

A new activity at Key Lake operation during the last half of 2013 has been the testing of a circuit within the mill to recover natural uranium from byproduct produced at two Cameco uranium fuel processing facilities in Ontario.

The byproduct is shipped to Key Lake in drums from Cameco's Blind River refinery and the Port Hope conversion facility. Both facilities are located in Ontario. The uranium content in the byproduct material averages 2.6% uranium.

The byproduct results from chemical processes that do not involve nuclear reactions.

Byproduct recovery was first proposed for Key Lake in 2002, but was put on hold pending improvements to the mill's water treatment process to remove additional molybdenum and selenium from water released to the environment.

The CNSC approved byproduct recovery as an activity in 2012 following five years of strong performance of Key Lake's improved water treatment system.

Testing of the byproduct recovery circuit is underway to confirm that the activity is safe for the environment. If there are no environmental concerns, then processing of this byproduct will become routine in future.

It is anticipated that operation of the byproduct recovery circuit at Key Lake could see up to 80,000 pounds of additional uranium recovered each year. The total volume of material being processed within the mill will add less than 1% to the volume of material going into Key Lake's tailings management facility each year.